Sustainable Materials

Materials that can be manufactured without causing irreversible changes to environmental systems.

An unequivocal definition of sustainable materials is hard to provide, as it depends on how we define something sustainable. In broad terms, sustainable materials are materials that can be manufactured without causing irreversible changes to environmental systems such as land and soil (geosphere), rivers, lakes, and seas (hydrosphere), air (atmosphere), and flora and fauna (biosphere). Generally speaking, products, and thus their material constituents, cause disturbance to the environment throughout their whole lifecycle as a result of extraction, production, processing, use, and disposal of the products.

The need for sustainable materials

Over the last 40 years, global resource extraction has doubled from 40 billion tonnes to 82 billion tonnes. As the world population grows and income levels rise, material production needs to keep up with the pace of demand. The rate of extraction grew 2 times faster than population growth over the last 10 years, signaling an increase in per capita resource consumption. The pressure on existing natural resources is not the only problem as 60% of materials produced globally are not recycled, composted, or reused. With the increase in consumption, the generation of waste becomes an inevitable problem. The disposal of waste and its low recycling rate is not just dictated by logistical problems. Technical, political, and economical hurdles hinder the rise of recycling rates globally.

Growing concerns over meeting global material demands sustainably

Emissions are generated every stage of material life cycle.

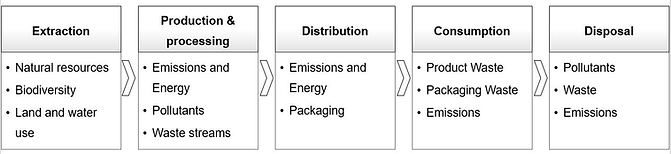

The lifecycle of materials (i.e., from extraction to production to consumption to disposal) has multifaceted implications on the environment. Resource extraction—in particular mining activities—affects the various ecospheres, described earlier, at and near the extraction site. The production and distribution process can create emissions and waste that may pollute the air, soil, and water. Recycling, a welcome solution to limiting the use of natural resources, requires energy and —often—a feed of virgin resources. Further, the final (il)legal disposal of waste into landfills and water streams can introduce toxic materials into the environment.

In this context, thinking about sustainable material extraction, production, consumption, and safe disposal, recycling, up- and down-cycling, and reuse become paramount for preserving the environment as well as the finite natural resources present on Earth.

Multidimensional impact of materials

The flow chart above maps the material life cycle to environmental impacts created at each stage

Categorizing materials based on sources and properties

There are thousands of different materials used every day by humankind. One popular categorization of materials is the one proposed in the official Material Flow Analysis manuals. This classification is described below.

Biomass

This category comprises agricultural products (e.g., cereals, fruits, vegetables), fodder, animal husbandry (e.g., meat, leather, milk), hunting and gathering (e.g., wild fish), and wood and timber.

Fossil energy carriers

This category include solid energy carriers (e.g., lignite, coal, peat), liquid and gaseous energy carriers (e.g., crude oil, natural gas), and derivatives of fossil energy carriers (e.g., plastics).

Nonmetallic minerals

This category mainly consists of materials used in construction (e.g., sand, gravel, marble, limestone), but it also includes salts and fertilizers used in agriculture.

Metallic minerals

This category includes all kinds of metals (e.g., iron, aluminum, copper) as well as their ores, concentrates, and products.

Materials belonging to these categories above are processed into products that are then sold/used by societies. Certain products can contain materials from all the four broad categories. For example, a car contains metallic minerals (e.g., chassis, engine), nonmetallic minerals (e.g., glass), fossil energy carriers (e.g., plastic parts, tires), and in some cases biomass (e.g., leather seats). In other cases, a product can contain a single material category (e.g., a chain link fence is made using only metallic minerals). The above classification is useful to determine approaches to material management throughout their life cycle.

Examples of sustainable materials

Bioplastics from wood

A research team led by Dr. Yuan Yao and Dr. Liangbing Hu successfully created bioplastic from wood byproducts using a simple manufacturing process. Currently available bioplastic materials don’t have comparable mechanical strength to fossil fuel plastic. However, this bioplastic has high mechanical strength, stability when holding liquids and UV-light resistance, is biodegradable, and has a lower life-cycle environmental impact when compared with petroleum-based plastics and other biodegradable plastics.

Mushroom-based Styrofoam

Several companies have created sustainable alternatives to Styrofoam using mushrooms. Among these are packaging materials created using low value agricultural waste streams as feedstocks for growing mushrooms. The mushrooms in turn are used to create biodegradable and recyclable packaging.

Watch Dr. Alessio explain the life cycle of materials, their impact on our environment and ways to mitigate the same.

Key Challenges

Exhaustion

All physical resources are finite. Some materials are so widely available that their exhaustion is of no concern, while others are very scarce. When a certain scarce material becomes in high demand for one or more specific applications, we are at risk of its depletion.

Limits to Recycling

While recycling is critical for prolonged usage of existing resources, there are thermodynamic limits to recycle and recover materials close to their original state. Both theoretical and empirical evidence show that the work/energy needed to remove every bit of impurity from a near-pure material increases infinitely as the purity requirements increase. Hence, considering the energy required to recycle waste materials, recycling may not be the end all and be all solution to waste management

Concentration

Modern industrial production has led to geographical concentration of key resources creating near-monopolistic scenarios for several resources. A well-known case is that of concentration of cobalt. As a leading producer of cobalt, Democratic republic of Congo can create artificial scarcity by limiting export of cobalt, a critical material for batteries used in electric vehicles

Progressive degradation

As a result of limits to recycling, the longer we keep a material in circulation through recycling processes, the more this material will degrade because of impurities. Many modern materials are created by combining various elements to achieve extremely specific set performances. These compounds can, for example, have very small percentages of rare metals that are very beneficial to the material during its lifetime, but end up as unwanted impurities during its recycling stage.

Waste

Every product that enters the socioeconomic sphere will eventually turn into waste, sooner or later. Thus, it is reasonable to assert that for each ton of materials that is created, there will be one ton of corresponding waste stream. Waste carries many challenges, from the physical collection and sorting to the introducing contaminants and hazardous substances into the ecosystem.

Emissions

Practically all industrial processes are associated with environmental emissions. These emissions might be airborne like CO2 and methane as well as contaminants that enter land and/or water. Even seemingly emission free activities generate indirect emissions. For example, while power plants operate on renewable energy, they still generate environmental impacts throughout their life cycle—albeit to a much smaller degree compared with their non-renewable counterparts.